Air Cooled Heatsink

Bonded Heatsinks, Soldered Fin Heatsink, Pressed Fin Heatsink, High Fin Density Extrusion, Huckey Puck Cooler, Profiles, Custom - details see: https://www.lightinghere.com/air-cooled-heatsink-10002256

| Type: Heat Sinks |

Advanced Air Cooling

Modern high power semiconductors must be cooled efficiently to take advantage of their high current capabilities. Conventionally air cooled extruded aluminium heat sinks have been an accepted cooling method used since the beginning of the semiconductor age. Now, with increasingly higher power densities, the thermal performance demand for effective heat dissipation exceeds the limits achievable with conventional extruded heat sinks.

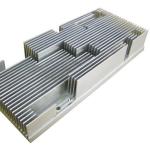

To meet the increased performance demand we have designed a new generation of power heat sinks -HIGH POWER BONDED FIN HEATSINKS.These heat sinks are produced by using an extruded aluminium base section into which separate fins are assembled. The joint between the extruded base section and the fin is made by using a special, high density epoxy developed together with a well-known producer of epoxy resin to guarantee optimal heat flow from the base

plate to the fins.

The thermal conductivity of this material is extremely high in comparison to other epoxy materials, and so enables the bonded fin heatsink to achieve a high thermal performance which exceeds all other assembly techniques. The manufacturing process has developed ensures error free products due to careful control of especially selected materials, surface preparations and strictly controlled assembly procedures. The particular manufacturing methods used result in a high strength attachment of the fins to base plate to resist mechanical stresses and stresses caused by high resonant frequency vibration without failure. Usually highly conductive aluminium is used for the base plate. The fins are made of pure aluminum and therefore offer a 15% better conductivity than extruded fins. Overall performance is therefore increased and the small loss incurred through the poxy interface is more than compensated for. Bonded fin heat sinks offer great advantages especially for high power design. Normally extruded heat sinks are only available with a fin height to fin spacing ratio of max 8:1.

Bonded fin heat sinks can be offered with a ratio of 30:1 or higher. This higher ratio gives more exposed surface area to the cooling air. More surface area means that more heat can be transferred away from the base plate and from the heat generating components. Therefore the junction temperature can be kept lower with bonded fin heat sink than with normally extruded heat sinks.

To meet the increased performance demand we have designed a new generation of power heat sinks -HIGH POWER BONDED FIN HEATSINKS.These heat sinks are produced by using an extruded aluminium base section into which separate fins are assembled. The joint between the extruded base section and the fin is made by using a special, high density epoxy developed together with a well-known producer of epoxy resin to guarantee optimal heat flow from the base

plate to the fins.

The thermal conductivity of this material is extremely high in comparison to other epoxy materials, and so enables the bonded fin heatsink to achieve a high thermal performance which exceeds all other assembly techniques. The manufacturing process has developed ensures error free products due to careful control of especially selected materials, surface preparations and strictly controlled assembly procedures. The particular manufacturing methods used result in a high strength attachment of the fins to base plate to resist mechanical stresses and stresses caused by high resonant frequency vibration without failure. Usually highly conductive aluminium is used for the base plate. The fins are made of pure aluminum and therefore offer a 15% better conductivity than extruded fins. Overall performance is therefore increased and the small loss incurred through the poxy interface is more than compensated for. Bonded fin heat sinks offer great advantages especially for high power design. Normally extruded heat sinks are only available with a fin height to fin spacing ratio of max 8:1.

Bonded fin heat sinks can be offered with a ratio of 30:1 or higher. This higher ratio gives more exposed surface area to the cooling air. More surface area means that more heat can be transferred away from the base plate and from the heat generating components. Therefore the junction temperature can be kept lower with bonded fin heat sink than with normally extruded heat sinks.